Harvesting of olives

Harvesting of the olives for the production of extra virgin olive oil begins in October, when the olives are green and continues until they turn a dark brown colour. Harvesting in recent years has been carried out with portable pulse olive harvesters, powered by a rechargeable electric battery. These machines increase productivity, reduce production costs and improve the viability of olive growing. They also cause less damage to the fruit and branches, and drop a very small percentage of leaves compared to wooden sticks. At the time olive nets or plastic cloths are placed on the ground, in which the olives drop’s and then collected.

Transport of olives

Every day the producers transport the olives they have harvested to the mill, either in jute bags or in plastic crates so that they are ventilated in order to avoid deterioration of the olives and degradation of the quality of the olive oil. There the olives are selected into categories and then the same day the olive oil is extracted.

Slicing - milling

After weighing, the olives are conveyed by a rotating screw conveyor to the crusher, where the plant cells are broken up, the olive oil drops are released and the olive paste is produced. Grinding of the olives is carried out at low speeds (1400/sec) because high speeds increase the temperature of the olive paste and contribute to the formation of emulsions. Milling is the first main stage in the processing of the olives for the production of quality and aromatic olive oil.

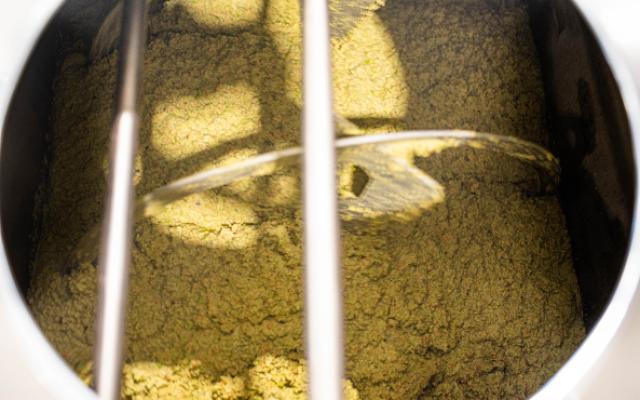

Malting of olive paste

The olive paste produced is transferred to the softeners (stainless steel basins with double walls and rotating fins) where the olive paste is stirred so that the small oil droplets resulting from the breakage of the olive cells can be combined into larger drops of olive oil. The mixing time must not exceed 40 minutes and the temperature of the olive paste must not exceed 27 °C ('cold extraction'), as this destroys the flavour of the olive oil. Each mixer is equipped with an automatic thermostat to regulate the temperature of the olive paste in each mixer to the desired level.

Centrifugation

After kneading the olive paste, it is transferred to the special two-phase FLOTTWEG - Z5E Decanter of our mill, where the olive oil is separated into two phases of oil-core, without the addition of water. It has an IMPELLER (movable diaphragm), thus achieving a higher oil productivity regardless of the olive variety.

The advantage is that the olive oil produced contains more phenolic substances and is therefore more resistant to oxidation, while retaining all its components, thus ensuring the beneficial properties of the oil.

Separation of olive oil

After the decanter, the olive oil passes through two latest generation Alfa Laval - UVPX510 separators, where the final separation of the olive oil from residual vegetable liquids takes place. The secret at this stage is that the water added must not exceed 27 degrees Celsius in order not to destroy the aromatic components of the olive oil. After the separation of the olive oil, its acidity is measured and we can taste the fruity taste and aroma of the extra virgin olive oil "IERA GOLD".

Storage of olive oil

The pure olive oil, it is led through stainless steel pipes for storage in the stainless steel tanks of our mill, based on its acidity and organoleptic characteristics. In the storage area, the temperature is kept low, and each olive oil tank is supplied with nitrogen gas, produced by the nitrogen generator of our mill, so that the olive oil does not come into contact with oxygen, in order to avoid oxidation. The aim is to keep our olive oil in the right storage conditions in order to maintain its quality and extend its shelf life.